Seawater desalination

Optimized hydraulic equipment for high-pressure feed boosting

World-leading pumps and energy recovery devices

- High-pressure feed pumps

- Circulation & booster pumps

- Turbocharger energy recovery devices

Efficient, reliable, and compact equipment suited to any RO system, from utility-scale seawater desalination to containerized units.

Increase desalination recovery: patented two-stage BiTurboTM SWRO design

Award-winning SWRO design

Distinction

Desalination Plant of the Year, 2020

Winner

Miriam Balaban Innovation Award, 2023

Shortlisted

Desalination Plant of the Year, 2024

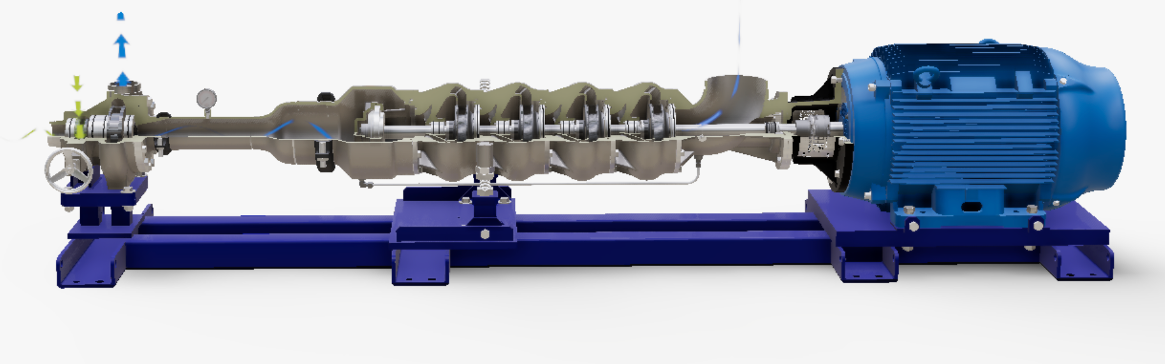

High pressure feed pumps

Best-in-class efficiency and reliability for high-pressure feed pumps.

Pair with a turbocharger to reduce pump size and energy consumption.

Circulation & booster pumps

High inlet pressure for use with:

- Isobaric energy recovery devices

- Semi-batch or closed circuit RO

- Multi-stage RO

We are constructing more desalination capacity than ever, but traditional single-stage membrane arrays dominate

Small increases to recovery come at the cost of higher biofouling, higher chemical consumption and shorter membrane life

Large arrays of isobaric ERDs also struggle to maintain consistent energy transfer, and introduce brine-feed mixing

As the push for sustainability and regulations limiting wastewater discharge volumes continue to increase, industrial water users are turning to water recycling and brine concentration through Minimal Liquid Discharge (MLD) and Zero Liquid Discharge (ZLD) facilities. Conventional approaches using evaporation are expensive, energy-intensive, and operationally challenging, making the case for maximizing recovery from waste streams more compelling than ever before.

However, achieving top brine concentrations beyond 100,000 ppm has traditionally been challenging for reverse osmosis (RO) technology. At every scale, the need for a simple and reliable solution to the membrane brine concentration challenge is clear. Let us help you push the boundaries of what RO technology can achieve.

Advantages of multi-stage, ultra-high-pressure RO using interstage turbochargers:

- Achieve top brine concentration up to 120,000 ppm without complex system configurations or challenging operating conditions

- Simple and reliable solution to the membrane brine concentration challenge

- Energy-efficient and cost-effective compared to conventional approaches using evaporation

Read the technical paper linked below to find out more about applying ultra-high-pressure turbochargers to industrial wastewater treatment and ZLD.

Find out more:

- Product specifications: text here

- Technical paper: text here

Contact our sales team to find out more about our products and services.

Interstage boosting is commonly used in brackish water reverse osmosis (BWRO) to balance flux between multiple RO stages. This achieves more stable membrane performance and higher recovery rates.

Using a turbocharger for your system's interstage boosting needs avoids using additional energy, and saves CAPEX on a booster pump, motor and variable frequency drive. It is also highly compact and operates with close to zero noise and vibration.

Interstage boosting is an ideal solution to handling high recovery applications or variable feedwater quality. See the case study below to find out more.

Find out more:

- Product specifications: Learn more about the HPB turbocharger

- Technical guide: In-depth study of centrifugal energy recovery devices

- Case study: Addressing variable feed quality using interstage boosting.

Contact our sales team to find out more about our products and services.

As the push for sustainability and regulations limiting wastewater discharge volumes continue to increase, industrial water users are turning to water recycling and brine concentration through Minimal Liquid Discharge (MLD) and Zero Liquid Discharge (ZLD) facilities. Conventional approaches using evaporation are expensive, energy-intensive, and operationally challenging, making the case for maximizing recovery from waste streams more compelling than ever before.

However, achieving top brine concentrations beyond 100,000 ppm has traditionally been challenging for reverse osmosis (RO) technology. At every scale, the need for a simple and reliable solution to the membrane brine concentration challenge is clear. Let us help you push the boundaries of what RO technology can achieve.

Advantages of multi-stage, ultra-high-pressure RO using interstage turbochargers:

- Achieve top brine concentration up to 120,000 ppm without complex system configurations or challenging operating conditions

- Simple and reliable solution to the membrane brine concentration challenge

- Energy-efficient and cost-effective compared to conventional approaches using evaporation

Read the technical paper linked below to find out more about applying ultra-high-pressure turbochargers to industrial wastewater treatment and ZLD.

Find out more:

- Product specifications: text here

- Technical paper: text here

Contact our sales team to find out more about our products and services.