- Home

- Reverse Osmosis

- Optimal RO Designs

- Mega-scale SWRO: PowerLine

Powerline

Optimized seawater desalination

-

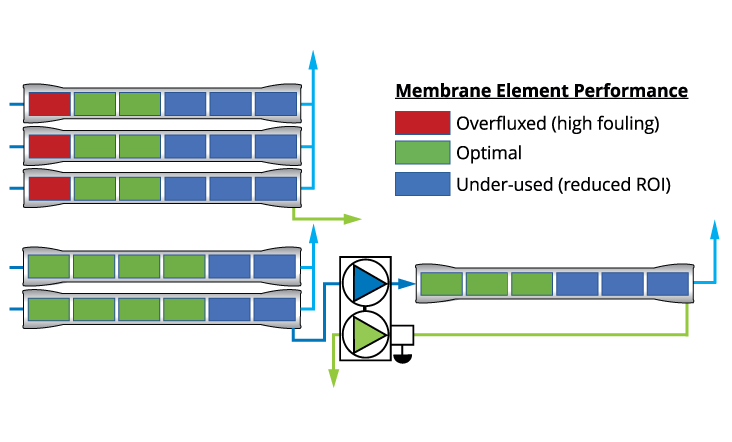

Streamline membrane performance

-

Maximize hydraulic efficiency

-

Eliminate avoidable electrical losses

Challenges

Membrane biofouling

VFD-related energy losses

Limited pump efficiency

Solutions

Optimized multi-stage SWRO

reduce fouling and extend membrane life

Minimal reliance on VFDs

reduce HVAC requirements and electrical losses

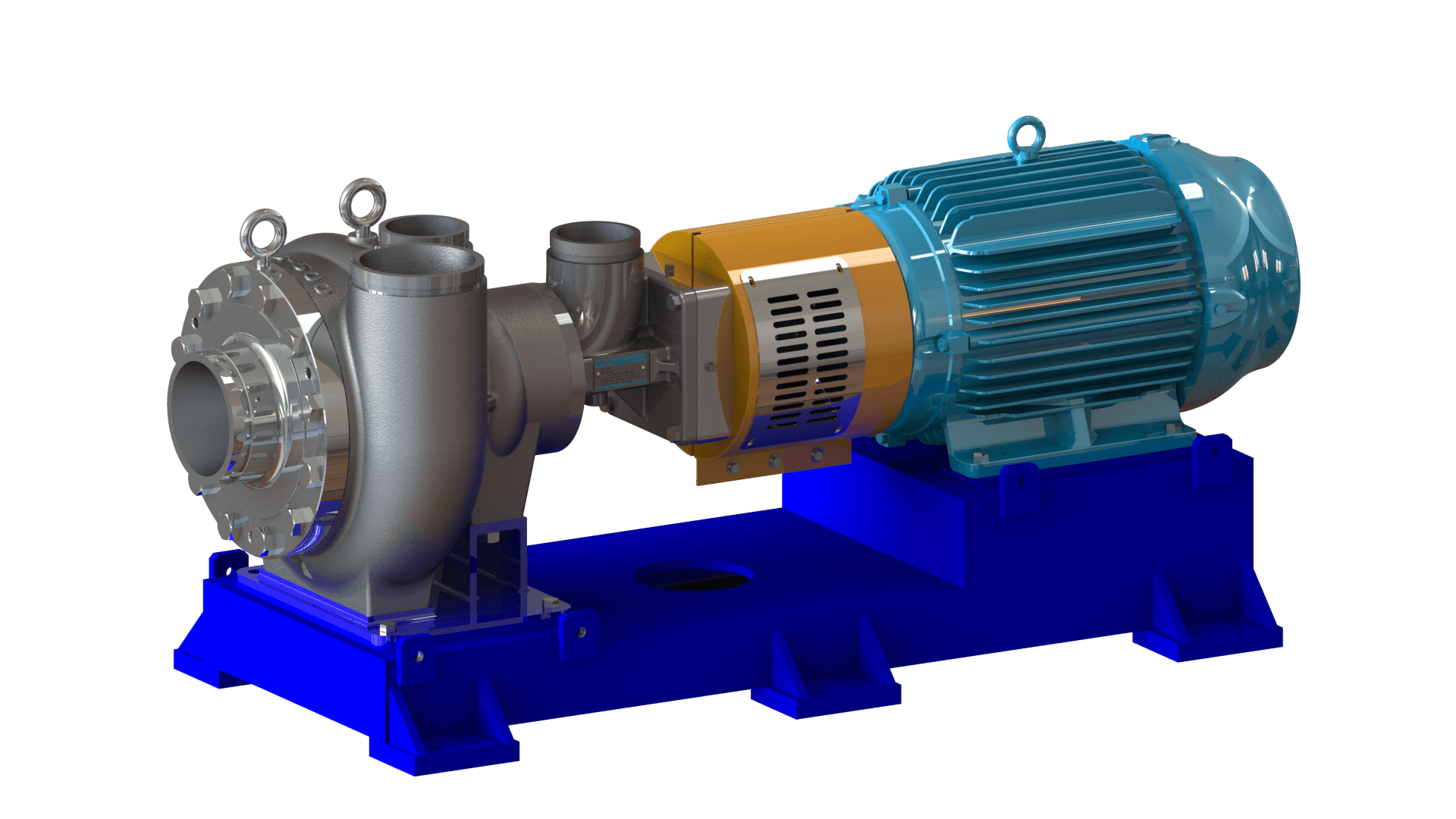

c.90% hydraulic efficiency

optimized hydraulic designs

REDUCE ENERGY CONSUMPTION

- 5% higher pump efficiency

- Up to 5% lower energy consumption through elimination of losses and more efficient pumping

- Handle entire feed flow with c.90% efficient impellers

- Up to 70% lower HVAC requirements

OPTIMIZE MEMBRANE CONDITIONS

-

Up to 30% longer membrane life

-

Up to 80% higher cross-flow

- Lower fouling with up to 40% lower membrane beta

- Smaller second pass: up to 30% lower permeate TDS

IMPROVE PLANT RELIABILITY

- Up to 50% lower maximum differential pressure for better safety and reliability

- Eliminate VFD-related downtime by using smaller, easily reparable drives